There are 10 images on this page.

The transmission on the

car will consist of the Fiat 5 speed gearbox ( because it fits the engine,

is strong and we have them in stock.), and a Ford Sierra 7" or 7 1/2"

differential unit. Sierra drive shafts will also be used. There are two sizes

of Ford differential and the sizes indicate the size of the crown wheel. My

first choice of diff. will be the 7" unit because it is lighter but it

it proves weak I can fit the 7 1/2" unit. The mounting points for each

housing vary slightly but I will make the chassis accept both sizes. The propshaft

will be a custom made item with lightened parts.

The steering will be rack and pinion using a rack built to my specification.

Column will be CDS rotating in needle roller bearings with a quick release

steering wheel. I will try to make the whole steering system as solid as possible

to give the greatest amount of feed back

As I intend to use the car for tarmac rallying the brakes will have to be

big to cope with the demands. At the front I will use the largest vented discs

I can fit with 4 pot alloy calipers. ( Alloy calipers to keep the unsprung

weight down.) The rear will have Ford discs and calipers as intended for the

upright. Master cylinder choice will be determined by considering the relative

sizes of the front and rear brakes, coefficient of friction of the tyres and

weight transfer when braking. A balance bar will fine tune the choice and

a proportioning valve will cover the varying tyre grip on different road surfaces.

( Wet and dry etc)

The gearbox was stripped

and rebuilt. The Price of components from Fiat was very high. It would cost

£750 to replace syncro`s , selectors and bearings. In this picture I

have lock wired the bolts which hold the selectors to the rods. This is for

peach of mind.

-----------------------------------------------------------

I had never rebuilt a

gearbox before but I took my time and drew diagrams as I dismantled it. The

task was quite easy. I actually built one good gearbox from 3 poor ones and

fortunately one of them had syncro rings that were in very good condition.

-----------------------------------------------------------

A hydraulic clutch release

was required for a few reasons. Hydraulic clutches are easier to route and

they give a smoother action. The Fiat normally uses a cable and rather than

fit a slave cylinder on the release arm I used a concentric combined slave

cylinder and release bearing. This fits into the back of the bellhousing.

------------------------------------------------------------

The actual unit used

is Saab. This required the bellhousing to be machined and an adapter plate

making. Many of the race clutch suppliers sell their own based on the Saab

system but they are more expensive. Another advantage of using this system

is the thrust bearing is the correct size for the Ford clutch plate, the Fiat

one is too small.

----------------------------------------------------------

The gearbox, propshaft

and the differential. The propshaft is steel but all the ends are lightened.

The length gives an indication as to the amount the engine is set back. The

propshaft was in balance to the repeatable accuracy of the propshaft balancing

machine. In other words the prop was showing a slight out of balance, but

if it was taken off the machine and attached again the out of balance would

be in a different position.

----------------------------------------------------------

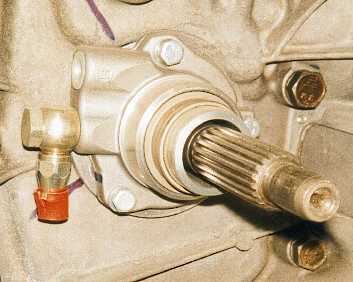

The Fiat prop. normally

has a rubber guibo on the gearbox, this is unsuitable for my short single

piece shaft so I had to machine an adapter to convert the Fiat 3 bolt fitting

to the 4 bolt fitting on a standard 1300 series flange. There are also 2 kinds

of output on the Fiat gearbox, I used the one which would be lightest. This

is where the reverse sleeve yoke slides out of the gearbox.

-----------------------------------------------------------

The adapter is doweled

onto the 3 prong spider and dowels are provided for drive to the propshaft.

Concentricity of the register on the alloy adapter is important so the propshaft

runs true.

----------------------------------------------------------

When using racing discs

you have to design and make your own mounting bell. The advantage of this

is you can place the disc where ever you want. I machined the mounting bells

from 2014A in the T6 condition. They will also be hard anodised.

----------------------------------------------------------

When machining the mounting

bell it is important to have a large a radius as possible at each change in

section. The holes to bolt the disc to the bell were drilled and reamed with

the disc in position, using the disc as a drilling jig. The holes were then

peened.

-----------------------------------------------------------

The AP Racing 4 pot road

caliper. It has dirt seals around the pistons. The price of these calipers

is quite reasonable. The calipers are radial mount, this gives more freedom

in the mounting brackets.

-----------------------------------------------------------