There are 10 images on this page

John`s words of wisdom.

READ THIS WHILE THE PICTURES ARE LOADING

A few welding tips.

When welding ensure that the metal is clean ( that is shiny, I normally

sand the area then scotch brite it.), the gap between the pieces not too large

and you can see what you are doing. (Clean mask and good light.) It also helps

a great deal if your hands are supported so you are not trying to weld in

mid air. I like to have support under my wrists. I also hold my breath when

TIG welding as I find the breathing can upset my poise. I often spend a considerable

time setting up the work or hand rests if I am welding on the chassis. My

welding mask is self darkening when you start welding. This is really worth

the money for TIG welding.

With MIG welding the common problems are not enough penetration, burning through,

or going off course. All these can be avoided by doing short runs ( 10 to

15mm ) on quite a high setting. Alternate the position of the runs and you

will also minimise distortion.

Robin fabricated a new

top surround for the windscreen from

flat sheet steel. This was rolled around a piece of tube in the

vice with a hammer. When bending with a hammer you must

work the metal a little at a time or stretching will occur.

-------------------------------------------------------------

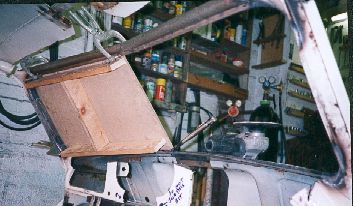

The new windscreen surround

from the inside. The piece of

wood is used to replicate a pane of glass and ensure the new

lip is flat and in line with all the other new lips.

------------------------------------------------------------

The new top surround

is capped off with a flat piece of sheet.

Robin welded a 5mm piece of plate under the capping sheet,

this could be tapped later to hold the hood frame pegs in

position.

------------------------------------------------------------

A general view of the

new surround, showing how the roof is

cut away. This will be cut off later but is retained at present to

give reference when making the new surround.

------------------------------------------------------------

The wind screen surround

finished. Robin has sprayed the

work in some old paint to make the job look neat and to

prevent rust.

------------------------------------------------------------

Now all the body modifications

are done Robin removed the

roof. He has done many convertible conversions on Minors

so he knows where to cut.

-------------------------------------------------------------

The floor was cut away

from the rest of the body and

discarded. As I am building a new chassis the original Minor

floor is not required. Cutting out the floor was quite simple as

most of it was separate due to the new panels that had been

put in. Also I could cut the floor down the middle and move

the two halves towards each other away from the body sides.

------------------------------------------------------------

The body shell that is

left after all the floor is cut out. Not

much of the body remains but it is all that I require.

-----------------------------------------------------------

The body had to be attached

to the chassis with consideration

given to where the major forces are going to be on the body.

The door pillars will have to be the strongest and in every

direction, up down, side to side etc.

------------------------------------------------------------

The mounting method decided

upon for the front consisted of

four tubes welded to the chassis pointing forward and the

body mounts slot into them. This picture shows the method

used to ensure each tube is in line with the others. The long

tube makes it easier to ensure it is level and parallel to the

centre line of the car.

------------------------------------------------------------